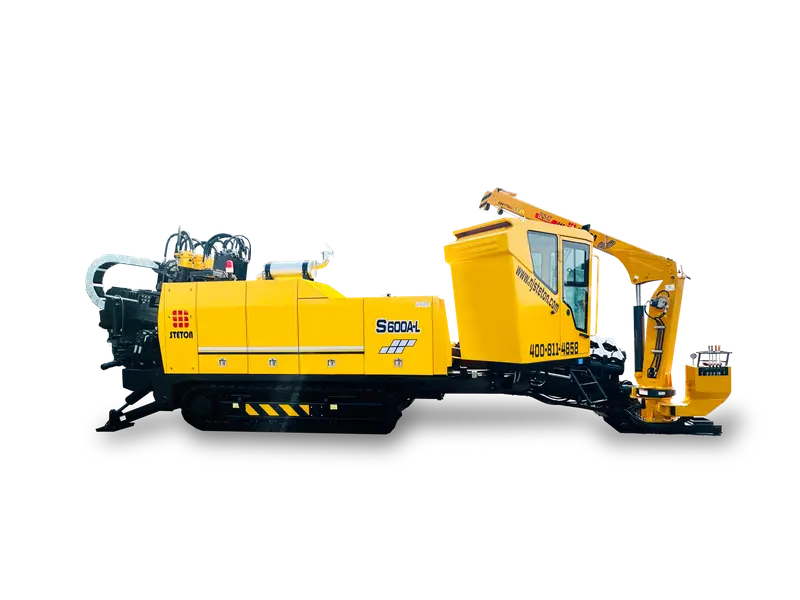

Various specifications of horizontal directional drilling machines are composed of drilling system, power system, directional control system, mud system, drilling tools and auxiliary tools. Their structure and functions are described as follows:

1. Drilling rig system: it is the main body of the drilling operation and towing operation of the crossing equipment. It is composed of the main machine of the drilling rig and the rotary table. The main machine of the drilling rig is placed on the drilling rig frame to complete the drilling operation and towing operation. The rotary table is installed at the front end of the main machine of the drilling rig, connected with the drill pipe, and meets the requirements of different operation conditions by changing the rotary table’s steering and output speed and torque.

2. Power system: composed of hydraulic power source and generator, the power source is to provide high-pressure hydraulic oil for the drilling rig system as the power of the drilling rig, and the generator provides power for supporting electrical equipment and construction site lighting.

3. Direction control system: The direction control system is a directional tool to guide the drill bit to drill correctly by monitoring and controlling the specific position and other parameters of the drill bit underground through the computer. Because of the control of the system, the drill bit can drill according to the design curve. Currently, there are two types of direction control systems, portable wireless and wired.

4. Mud system: The mud system is composed of mud mixing tank, mud pump and mud pipeline, providing the drilling system with mud suitable for drilling conditions.

5. Drilling tools and auxiliary tools: various tools used for drilling and reaming during drilling. Drilling tools mainly include drill pipes, drill bits, mud motors, reamers, cutting knives and other tools suitable for various geological conditions. Auxiliary tools include snap rings, rotary unions and drag heads of various pipe diameters.